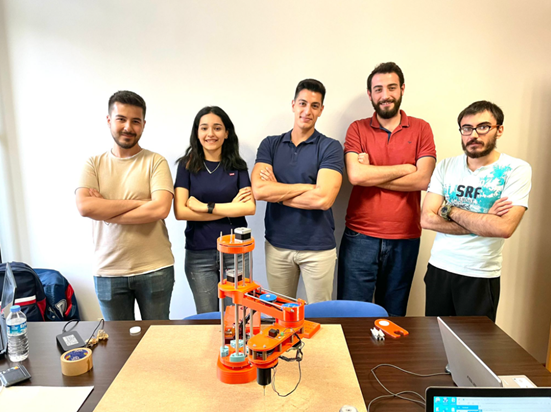

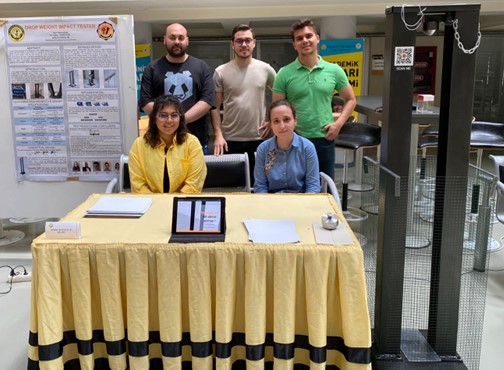

Proje Öğrencileri: O. ÇALISICI, S.A. KINACI, B. AKISOGLU, I. KOLTAN, M. YUKSEL

Abstract :

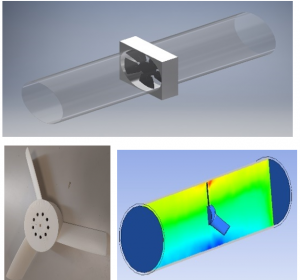

The project covers project planning, production planning, test planning, design changes, re-production, re-testing, project final report, project presentation, and implementation plan. It outlines future work with determined deadlines and material procurement. Challenges in production planning include production capacity, utilization, and output balance. The test plan outlines testing approach, objectives, timelines, and resources. Changes in three primary factors were used when constructing the test plans. Design changes were made due to material availability, cost, and customer requests. The final design was produced and tested, with a conceptual design presentation and the creation of a Gantt chart. The project presentation covers six main topics and includes 3-D modeling of the test setup.