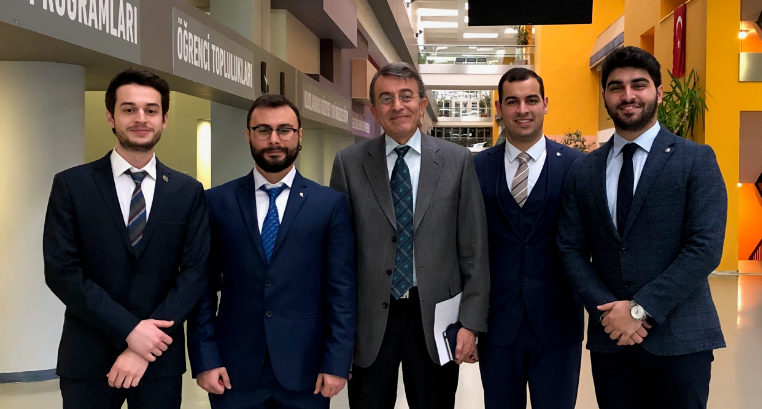

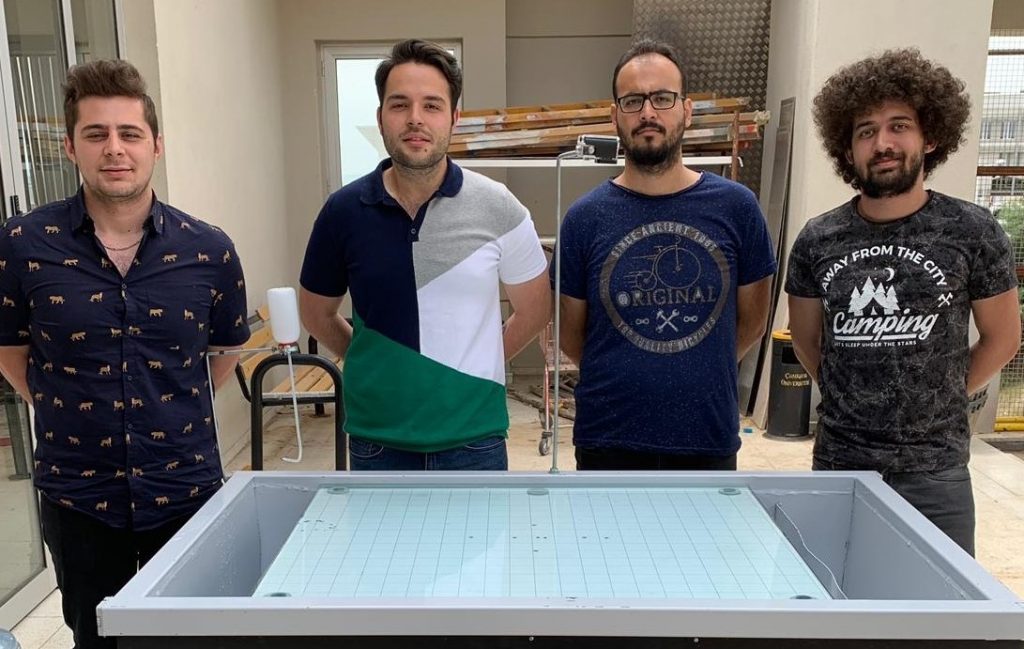

Proje Öğrencileri: S. BAŞKALE, İ. BOZOKLU, F. DOKUR, B. KARAKURT, E. AKIN

Abstract : The project is sponsored by Optima. After conducting research on the company, a start-up meeting was held with the company to discuss our project. A timeline for our group was determined at this meeting. It was determined how to work and what to do on a weekly basis. This timeline is of great importance for the operation of the project. Then, features and design requirements for automatic garage door design were determined. As a result of meetings with our sponsor and supervisor, the appropriate design was indicated. For the motor to be used in the project, the motor selection was made from a company determined by the sponsor. Automatic garage door panel, motor, reducer, sliding and driving mechanism was decided. Depending on motor power and output torque, the mathematical calculations of the gear unit have been made. In order to create shaft and sliding mechanism, necessary mathematical calculations were made. Designs based on these calculations were continued under the control of our industrial and academic supervisor. During the production phase, the sponsor company was sent to the list of materials to be used in the project. The price list was determined. After the procure of material, production was started in machining. We worked with different collaborative companies to manufacture some parts. After the part production was completed, the assembly process was carried out. The system was tested after assembly.